Pentafluoroethoxy cyclotriphosphazene FPN-100 for flame-retardant electrolyte

High safety and high environmental adaptability are the basic requirements of lithium-ion power batteries for electrolytes. With the continuous improvement and renewal of electrode materials, the requirements for matching electrolytes are becoming higher and higher. Due to the extremely difficult development of new electrolyte systems, conventional electrolytes with carbonate-based organic solvents and lithium hexafluorophosphate will still be the mainstream choice for power batteries for a long period of time in the future. In view of the above situation, in order to adapt to the development of electrode materials and power batteries for different purposes, a small amount of additives is generally added to the conventional electrolyte to meet specific application requirements. For example, anti-overcharge additives and flame retardant additives can greatly improve the safety performance of the battery under abuse conditions such as overcharge, short circuit, high temperature, needle puncture and thermal shock; adding positive electrode film-forming additives can meet high voltage to a certain extent Charge and discharge requirements of materials.

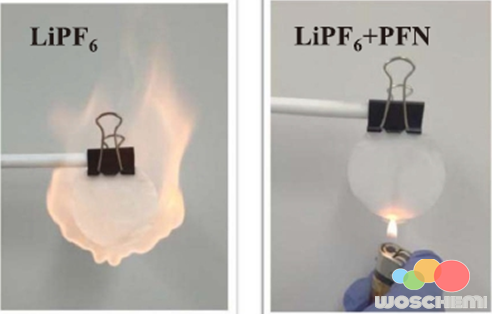

At present, there are many studies and reports on cyclotriphosphazene compounds. Among them, ethoxypentafluorocyclotriphosphazene (FPN100) has received greater attention. It has excellent flame retardant properties and is suitable for batteries under general conditions. There is almost no impact on performance [1].

As a flame retardant additive for lithium battery electrolytes, FPN100 is already familiar to everyone, but there are few research reports on other functions. Recently, Liu et al. [1] reported that FPN100 is expected to be used as an additive for high-voltage lithium battery electrolytes. For the LiNi0.5Mn1.5O4 battery system, the cycle performance comparison under the conditions of 0.2C and voltage 3.5-4.9V is shown below. The capacity retention rate of the battery system with FPN is significantly better than the system without FPN100.

For the LiNi0.5Mn1.5O4 system with FPN and without FPN electrolyte added, cyclic voltammetry experiments found that the system with 5wt% FPN added has a small oxidation current peak at 3.8V during the first cycle, while in the system without FPN added There is no presence in the system, indicating that FPN has undergone an oxidation reaction, and the oxidation potential of FPN is lower than the decomposition potential of LiPF6-based electrolyte (4.8 V Li+/Li). The above results indicate that FPN molecules have been oxidized on the surface of the positive electrode material to form a protective layer before the electrolyte is decomposed, which inhibits the oxidative decomposition of the electrolyte and improves the high-voltage performance of the positive electrode material.

In summary, in addition to being a flame retardant additive, FPN is also expected to be used as a high-voltage lithium battery electrolyte additive to form a protective layer on the surface of the high-voltage cathode material, inhibit electrolyte decomposition and electrode corrosion, and improve battery cycle stability.