二乙基次膦酸铝(ADP)Aluminum diethylphosphinate (ADP)

Aluminum diethylphosphinate (ADP)

product description:

This product is a phosphorus-nitrogen system environmentally friendly halogen-free flame retardant, a white powder, organic phosphinate. It is insoluble in water and organic solvents such as acetone, dichloromethane, methyl ethyl ketone and toluene. It has the characteristics of high phosphorus content, good thermal stability and high flame retardant efficiency. It can be used as a flame retardant alone or in combination with other flame retardants, and both have good effects. The ADP-added polymer produces an expanded carbon layer during the combustion process to achieve the effects of heat insulation, oxygen isolation, and prevention of further flame diffusion on the surface. It does not hydrolyze or precipitate. It has good carbon formation and self-extinguishing properties. It is suitable for thermoplastics and thermosets. plastic.

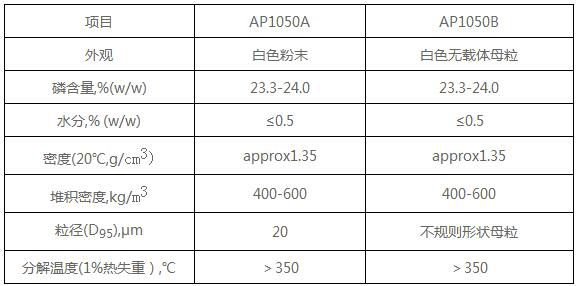

Technical indicators:

Diethyl aluminum hypophosphite flame retardant is mainly used in thermoplastic elastomer TPE and thermosetting plastics. Because of its high phosphorus content, its flame retardant efficiency is high. Diethyl aluminum hypophosphite flame retardant is especially suitable for polyester and PA fiber reinforced. It is suitable for glass fiber reinforced and non-reinforced grades. Flame retardant polyester compounds have good physical and electrical properties. In the addition of PBT, the addition amount of diethyl phosphinate aluminum flame retardant is 20% (parts by weight), and its material can reach UL 94 V-0 classification (thickness 1.6-0.8 mm) when used as an electrical accessory. In the addition of PET, when the addition amount is 15% (parts by weight), it can reach the UL 94 V-0 classification. The amount of flame retardant added will vary depending on the polymer grade, processing conditions and glass fiber addition.

In the treatment process, the polyester material should generally be pretreated before adding diethyl aluminum hypophosphite flame retardant. If possible, the water content of materials PBT and PET should be less than 0.05% and 0.005% (parts by weight) respectively. The aluminum diethylphosphinate flame retardant does not need to be dried in advance. If the moisture content of the flame retardant is required to be very low, we recommend pre-drying (for example, drying at 130°C for 3 hours). The mixing conditions should be determined according to different situations. Pay attention to ensure that all ingredients are evenly dispersed, and the melting temperature of the polymer should not exceed 320°C.

To

Packaging and storage

25KG/box, stored at dry room temperature.